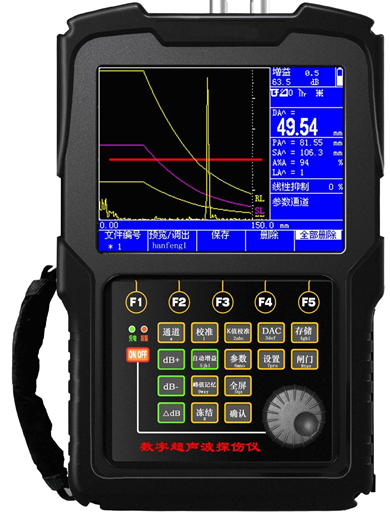

- ZD720 Portable Ultrasonic Flaw Detector

ZD720 Portable Ultrasonic Flaw Detector

Rugged ZD720 durability, 8 hours of bat tery use, easy keys operation, outstanding ultrasonic performance, and now “square wave pulser” and “color leg” combine to form a powerful portable ultrasonic inspection tool with powerful Lithium Ion battery pack.

The ZD720 combines the power ful advantages of digital design with the detailed dynamic echo informa tion that was previously only possible with an analog display. The high resolution color LCD display, 160 Hz update rate, and “single shot” measurement tech nique produce a fast, smooth response for immersion and critical weld testing. The quality, durability, dependability and ease of use remains on the BSN80. From rugged field inspections to high resolu tion thin measurements, long acousti cally clean materials, and immersion systems work, the BSN60 extends the range of applications that a portable instrument can perform.

Performance features

Parameter Setups Files Up to500 files stored instrument parameter setups.

A-Scan Files Up to 500files including operation parameters plus A-scan, the stored datasets can be easily previewed, recalled and exported to a computer for edit and printing.

Thickness Files Up to 10,000 thickness values stored in single thickness file.

PC Communication Bi-directional RS232-USB adaptor connected with PC.

DAC/ TCG DAC or TCG with a maximum of 16 reference echoes, 4 other curves can be displayed with variable dB intervals. DAC curves can be varied with variable dB or variable range.

Readings Up to selectable 26 readings (Sound path, projection distance, depth, echo height, and ERS.)

B-Scan Selectable corrosion-featured B-scan and full-featured B-scan

Square Wave Pulser Square wave pulsers allow optimum probe matching by adjusting pulse width and voltage. Difficult to penetrate metallic applications and especially non- metals inspection like composite materials are optimized. Pulse width is tunable up to 1000 ns in 10 ns steps. Pulser voltage is adjustable from 20 to 500 V in 10 V steps.

Rectification Positive half-wave, negative half-wave, full-wave, RF

Reject (suppression) 0 to 90% linear

Units Inch, millimeter, or microsecond selectable

Languages Selectable English, Chinese

Gate Monitors Two independent flaw gates controllable over entire sweep range

Measurement Modes Zero-to-first, multi-echo with selectable flank or peak detection

TTL Output Three independently assignable outputs, instantaneous, timed, latched with visual LED and audible horn alarms

Alarm Selectable positive logic, negative logic, upper limit thickness or lower limit thickness alarm mode

Curved surface correction Corrects sound path information when using an angle beam transducer to circumferentially inspect a curved surface for either tubular or bar inspections.

Auto Calibration Measurement and setting of sound velocity and probe delay using two known calibration echoes (2-point calibration)

Auto Gain Adjust automatically the system sensitivity to bring (increase or decrease) the measured echo to the suitable echo height. Echo height setting value from 10 % to 90 % of the screen height.

Display Screen 5.7 inch LED backlight TFT_LCD, display resolution 320 x 240 pixels, selectable 4 scheme colors and 8 A Scan colors.

A-Scan Resolution Standard 200 x 220 pixels, or 100 x 220 pixels

Display Update Rate 160Hz

Specifications

Range 1 to 10,000 mm at steel velocity, range selectable in fixed steps or continuously variable

Material Velocity Continuously adjustable from 100 to 20,000 m/s, 33 selectable material velocities

Display Delay -5 to 3400 μs in steel (dependent on range)

Probe Delay(Zero Offset) 0 to 100 μs

Damping 50, 75, 150, 500 ohms

Gain 0 to 110 dB adjustable in selectable steps 0.2, 0.5,1, 2, 6, 12dB, user definable, and locked

Pulse Repetition Frequency 20 to 1K Hz

Bandwidth 0.2 to 20 MHz with 3 selectable broadbands

A/D Sample Rate 100MHz (Hardware Rate)

Probe Connections BNC

Power adapter 9VDC, 110-220VAC

Battery Power 7.4V, 6600Ahr Lithium Ion Battery Pack

Battery Life 12 hours on Li-Ion Battery Pack

Operating temperature -10~60℃

Stored temperature -25~70℃

Size 230mm×150mm×45mm

Weight 1.0kg with Li-ion battery pack

Horizontal Linearity Error ≤0.1%

Vertical Linearity Error ≤3%

Echoes Resolution >30dB

Sensitivity Margin >60dB (200mm,Φ2,flat bottom hole)

Dynamic Range >30dB

Standard Configuration

Portable ultrasonic flaw detector 1

Straight-beam probe 1

Angle-beam probe 1

Probe cable 2(Connected with straight-beam probe and angle-beam probe)

AC adapter/charger 1(Include AC power cable)

Recommended accessories

USB adapter 1 (USB cable)

Battery Pack 5400mAh Li-ion battery pack

Calibration Block Supply according to customer requirements

Probe Supply according to customer requirements

PC software 1(Include DataPro software and RS232 serial PC cable)