- ZD410 Integral Floor Thickness Gauge

ZD410 Integral Floor Thickness Gauge

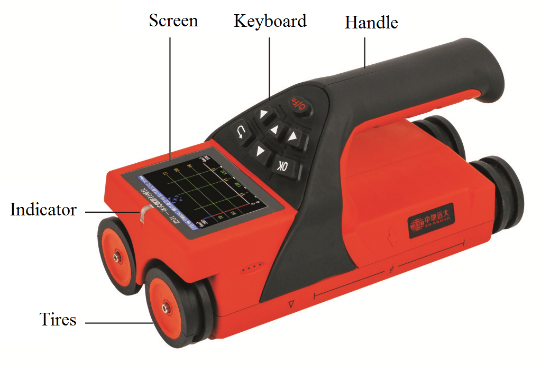

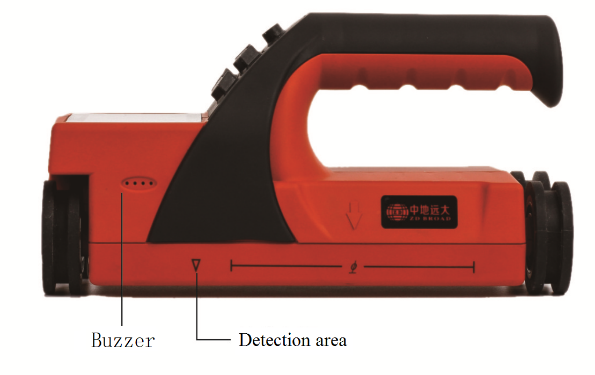

a)Top view

b)Left view

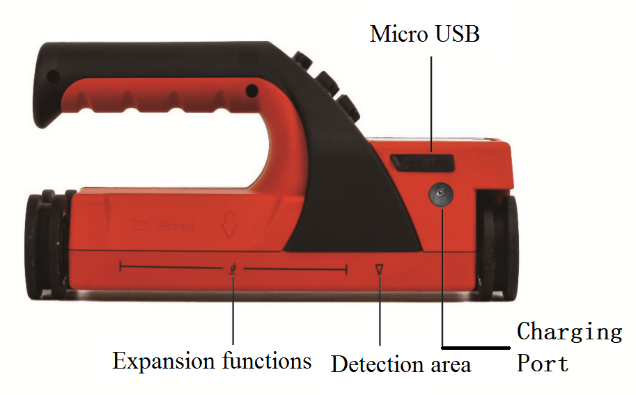

c)Right view

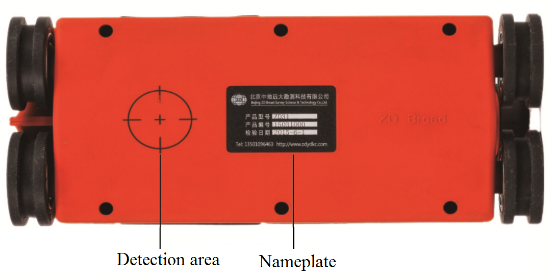

d)Bottom view

Schematic diagram of host appearance

1.1 Introduction

ZD410 Integrated Floor Thickness Gauge is mainly used for non-destructive testing of thickness measurement of concrete structures or other non-ferromagnetic media, for example: non-ferromagnetic thickness measurement of cast-in-situ floor, wall, beam, column, wood and ceramic; The unique design of the receiving probe and the host is one, only need to test on the corresponding surface of the transmitting probe (floor, etc.) to measure the non-ferromagnetic thickness value.

1.2 Functions

1.2.1 Main Functions

1. Accurately measure the thickness of concrete, floors, shear walls, beams, columns, etc.

2. Storage, viewing and transmission of inspection data.

1.2.2 Special Functions

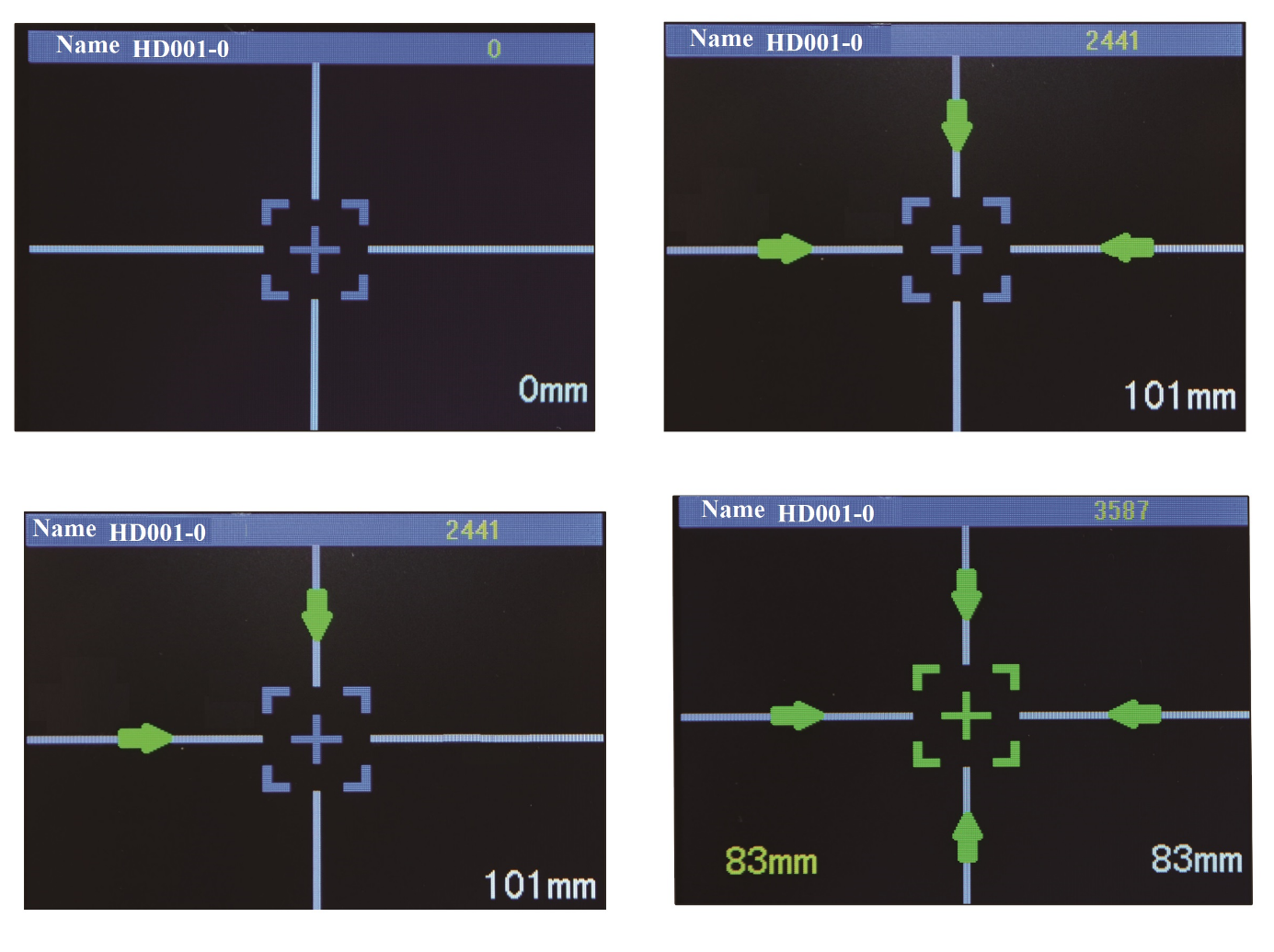

1.Real-time display of measured values and automatic locking of true thickness;

2.With compensation type thickness detection function, it can compensate the detection of steel bars in concrete, etc., and has higher measurement accuracy. (Limited to different models)

3.Fast real-time positioning, real-time display of the transmitting probe position, and fast positioning through direction indication;

4. Single-hand grip and operation design, easy operation and fast automatic search for the position of the transmitting probe;

5. Automatically store calibration values to achieve fast measurement and reduce the troublesome procedures of each calibration work before detection。

1.2.3 Main Features

1. 2.8-inch high-resolution color LCD screen (320 × 240 pixels), clearly visible inspection data no matter indoor or outdoor;

2. Integrated design of host and receiving probe, small size, light weight, easy to carry;

3. Using USB mode for data transmission and charging, you can quickly upload the stored data to the computer through the USB cable;

4. Built-in large capacity lithium battery, low design power consumption;

5. Data management, data storage, viewing, deletion and other functions, can store more than 200,000 measurement points;

6. Standard telescopic rod adopts professional and unique double 90 degree universal joint, which can be adjusted within 360 °;

7. Adopt four-wheel positioning method, the outer wheel is equipped with high-strength wear-resistant tires, which is easy to protect the wear of the instrument;

8. Optional professionally designed standard calibration test block。

1.3 Technical sheet

Table 1.1 Technical sheet

Items | Values | |

Thickness range (mm) | 20~450 | |

Screen | 320×240 | |

Measurement mode | Thickness detection, | |

Power supply | Built in high capacity lithium battery | |

Working hours | ≥16h | |

Launch probe Working hours | ≥26h | |

Communication | USB interface | |

Storage | 200K Measuring point of steel bar | |

Operation | Silicone keypad | |

Host | Size((mm) | 219×92×106 |

Weight(Kg) | 0.7 | |

Launch probe | Size(mm) | Ø100×110 |

Weight(Kg) | 0.5 | |

Telescopic rod | Size(mm) | Ø28×470(1.5m) |

Weight(Kg) | 0.4 |

Error range Range (mm) | Error range(mm) |

20~200 | ±1mm |

201-400 | ±2mm |

401-600 | ±3mm |

601-1000 | ≥±8mm |

Table 1.2 Error range of different thickness

1.4 Measurement interface

1.5 Standard Configuration

No. | Name | Unit | Quantity | Remarks |

1 | Product Host | piece | 1 | / |

2 | Launch The Probe | piece | 1 | / |

3 | Walkie Talkie | piece | 1 | / |

4 | Telescopicrod | piece | 1 | Converter head |

5 | Charger | piece | 1 | / |

6 | USB Cable | piece | 1 | / |

7 | User Manual | piece | 1 | / |

8 | Producer Certificate | piece | 1 | / |

9 | Warranty Card | piece | 1 | / |

10 | Packing List | piece | 1 | / |

11 | Software CD | piece | 1 | / |

12 | Product Suites/Box | piece | 1 | / |

13 | crayon | piece | 1 | / |

14 | Standard Block | piece | 1 | Optional accessories |