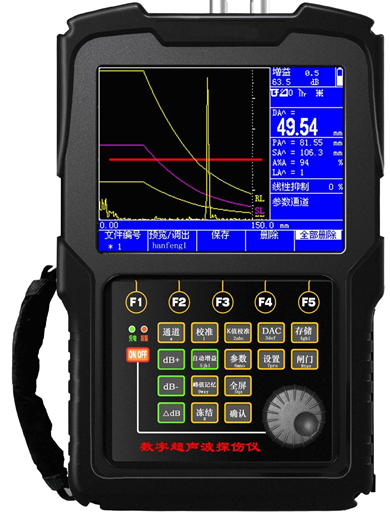

- ZD730 Coating Thickness Gauge

ZD730 Coating Thickness Gauge

Overview

The instrument adopts the magnetic and eddy current principle to measure in a non-destructive way .The instrument is a portable thickness-measuring meter, it can measure the thickness of coating and plating rapidly, non-destructively and precisely.It can be used both in lab and the work site.This instrument can be widely used in the inspection fields, e.g. manufacturing, metal processing, chemical industry and commodity inspection, etc.It is a gauge essential for the material protection.

The meter meets the following standards:

GB/T 4956─2003 Measuring Thickness of the Nonmagnetic Coating on a Magnetic Metallic Substrate, Magnetic

GB/T 4957─2003 Measuring Thickness of all electrically insulating coating on nonferrous metals, Eddy current Way

Measuring Principle

The instrument adopts the magnetic and eddy current principle to measure in a non-destructive way

Magnetic way (type F probe)

measure the thickness of non-magnetic coatings on magnetic metallic base (e.g. zinc, aluminum, Cr. Copper, rubber, paint, coating on the base of steel, iron, alloy and hard magnetic steel etc.)

eddy current way (type N probe)

measure all electrically insulating coating layers,such as lacquer,Varnish, paint,anodizing coating on nonferrous metals,also on austenitic VA steel materials.

Technical Specifications

Probe | F400 | F1 | F1/90° | F10 | ||

Measuring Principle | Magnetic method | |||||

Measuring range(mm) | 0~400 | 0~1250 | 0~10000 | |||

Min resolution(mm) | 0.1 | 0.1 | 10 | |||

Tolerance | One-point calibration (mm) | ±(3%H+0.7) | ±(3%H+1) | ±(3%H+10) | ||

Two-point calibration (mm) | ±(1%H+ 0.7) | ±((1%H+1) | ±(1%H+10) | |||

Minimum radius of curvature (convex) (mm) | 1 | 1.5 | flat | 10 | ||

Minimum measuring area(mm) | F3 | F7 | F7 | F40 | ||

Minimum thickness ofbasematerial(mm) | 0.2 | 0.5 | 0.5 | 2 | ||

Type N probe :

Probe | N400 | N1 | CN02 | |

Measuring Principle | Eddy current method | |||

Measuring range (mm) | 0~400 | 0~1250 | 10~200 | |

Min resolution(mm) | 0.1 | 0.1 | 1 | |

Tolerance | One-point calibration (mm) | ±(3%H+0.7) | ±(3%H+1.5) | ±(3%H+1) |

Two-point calibration (mm) | ±(1%H+0.7) | ±(1%H+1.5) | -------- | |

Minimum radius of curvature (convex) (mm) | 1.5 | 3 | flat | |

Minimum measuring area(mm) | F4 | F5 | F7 | |

Minimum thickness of base material(mm) | 0.3 | 0.3 | 0 | |