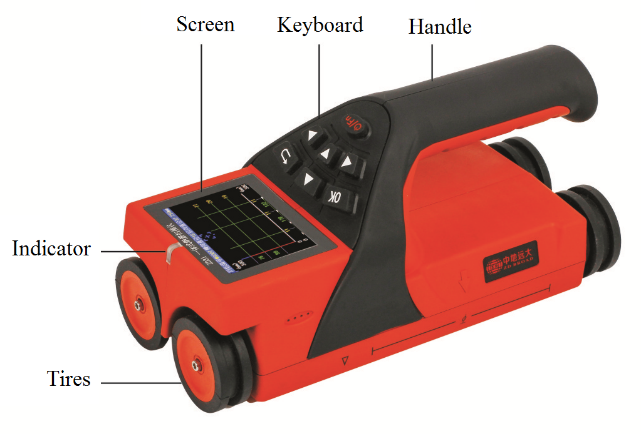

- ZD31 Integrated Rebar Detector

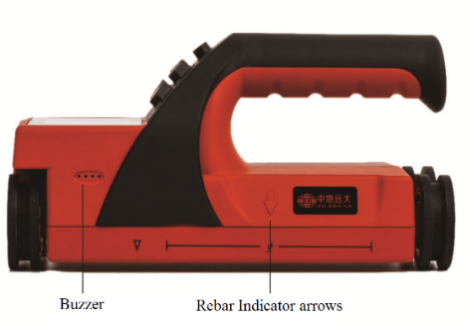

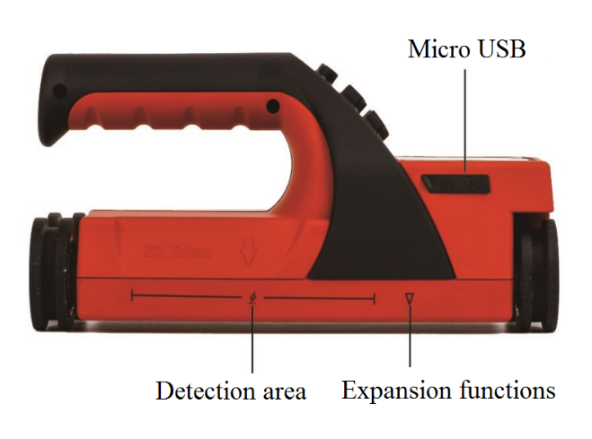

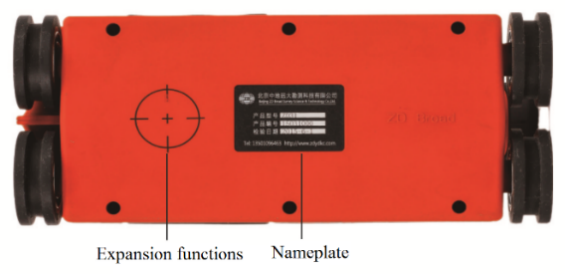

The appearance of ZD31Integrated Rebar detector is shown in figure 2.1.

a)Top view

b)Left view

c)Right view

d)Bottom view

Figure 2.1 Schematic diagram of host appearance

1.1 Introduction

ZD31Integrated Rebar Detector are mainly used for detecting the internal reinforcement position, the protective layer thickness,

reinforcement spacing and diameter of rebar. It can accurately draw the distribution map of the whole rebar, to provide test data

with high precision and high speed; the integrated structure of the host and the sensor coil, making it is convenient and quick

when carrying and field operation ; It is characterized in coil structure design, faster speed, higher accuracy, stronger resolution.

1.2 Functions

1.2.1 Main Functions

1. Accurately measure the thickness of protective layer of rebar;

2. Locate the position, trend and distribution of steel bars;

3. Measure the protective layer of steel bar and estimate the diameter of steel bar;

4. Storage, view and transmission of detection data.

1.2.2 Special Functions

1. The detection mode is intuitive, accurate, accurate display of steel bar position, spacing, protective layer thickness in the same screen;

2.Four kinds of single point measurement, grid detecting, waveform detecting and profile detecting are all implemented the deletion

operation of the wrong test data and graphics, which is easy to use in field test;

3. Complete at any time interleaved switching of X axis and Y axis grid scan testing process (i.e. direction coordinate axis) test, random

switching data and steel distribution will automatically continue the information before test, so as to improve the flexibility of the field test;

4. Single handing machine, operation design and four wheel positioning method, equipped with high strength wear-resistant tires, easy

to protect the wear and tear of the detector;

5.The automatic storage calibration value is used to realize rapid measurement and reduce the troublesome procedures before each check.

6. Analysis software can produce two-dimensional plan view and 3D three-dimensional view.

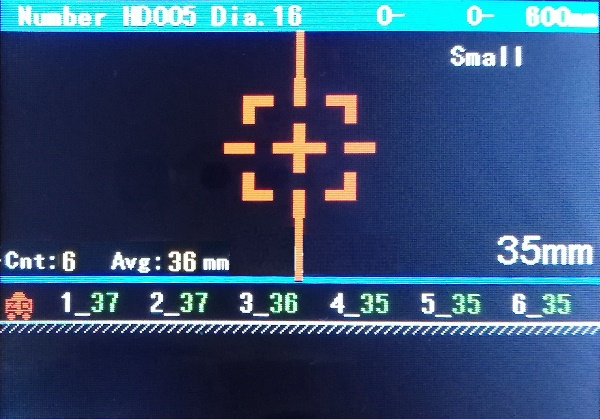

7. JGJ detection mode realizes 1-6 repeated tests of a single steel bar, and automatically calculates the average value;

1.2.3 Main Features

1. 2.8 inch high resolution color LCD screen (320 x 240 pixels), whether in indoor or outdoor, any situation can be clearly visible detection data;

2. Multi-coil structure design, faster, higher precision, stronger resolution;

Using USB mode data transmission and charging, you can quickly upload the stored

1. data to the computer through the USB.

2. With built-in high-capacity lithium battery, the power consumption is low, in the case of battery is full the standby time is about 16 hours;

3. Data management mode in the data storage, view, delete and other functions, can store about two hundred thousand rebar measuring point data;

4. The problem of reinforcing steel bar leakage is solved by using super dense tendon resolving power;

5. Select configuration Standard test block which can be configured with special and unique design;

6. Using the host and sensor coil integrated design, compact size, light weight, easy to carry;

7. Adjacent steel bar intermediate position real-time judgment, indicating light prompt, can avoid around the steel bar, easy drilling coring;

8. The instrument bag is shockproof, has a protective lining inside, and is equipped with a waterproof cover for easy carrying;

9. Equipped with medium and large steel bar detection software, it is convenient for professional data analysis, data processing and generating complete report in PC.

1.3 Technical sheet

Mode | ZD31 | |

Applicable range of Rebar(mm) | φ6~φ50 | |

Protective layer thickness range(mm) | Small range:1~80 Large range:5~185 | |

Maximum Allowable Error of Protective Layer Thickness(mm) | ±1 | 1~60 |

±2 | 60~100 | |

±3 | 101~120 | |

±5 | 121~160 | |

±8 | 161~185 | |

Applicability of Diameter Measurement (mm) | ϕ 6~Ф50 | |

Maximum Error of Diameter Measurement (Specification) | ±1 | |

Scanning mode | Thickness model, mesh model, profile model and waveform model, JGJ Testing | |

Scanning range | Borderless | |

JGJ Testing | Achieve single point 1-6 measurements, automatically calculate the average | |

Data transmission mode | USB\ wireless |

Screen | 2.8-inch High Resolution Color LCD Screen (320 x 240 pixels |

Power supply | Built in high capacity lithium battery |

Set shutdown time | 5min、10 min、15 min、30 min、60 min、90 min |

Working hours | ≥16h |

Screen | 320×240 |

Storage | 200K Measuring point of steel bar |

Communication | USB interface |

With error correction | -3.0~+3.0(±0.5、±1.0、±1.5、±2.0、±2.5、±3.0) |

Operation | Silicone keypad |

Remote Data Management | Implementing real-time data upload Online |

working temperature | -10℃~+42℃ |

Size(mm) | 219×92×106 |

Weight(Kg) | 0.60(Battery included) |

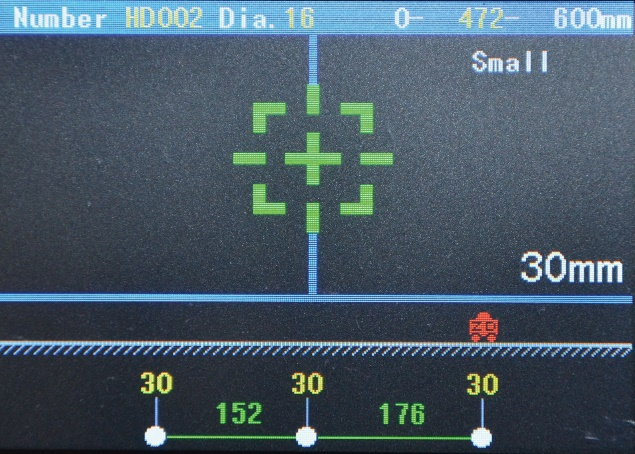

1.4 Measurement interface

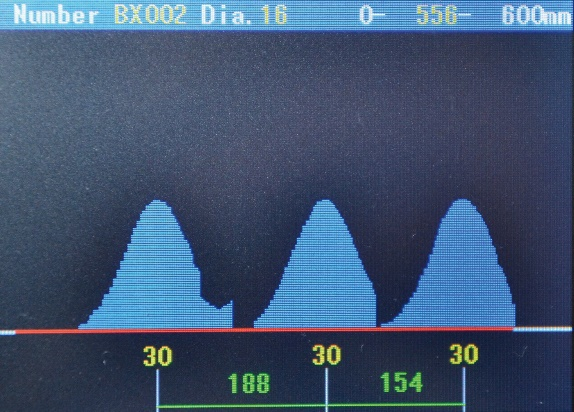

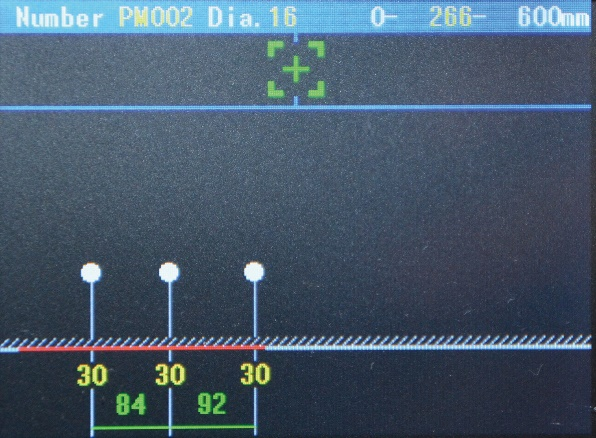

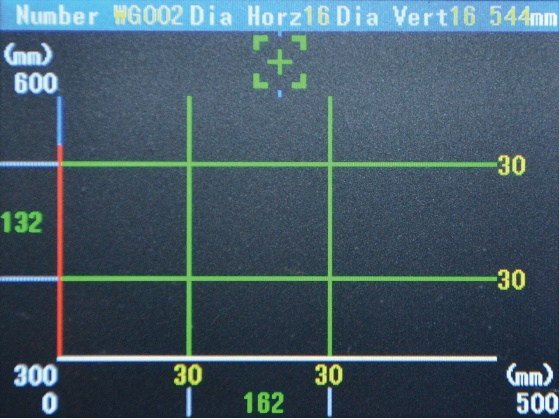

ZD31 Integrated Rebar detector The measurement mode is shown in Figure 1-5.

(1) Thickness model

(2) Waveform model

(3) Profile detection interface

(4) Grid detection、

(5)JGJ measuring interface

1.5 Standard Configuration

No. | Name | Unit | Quantity | Remarks |

1 | Product Host | piece | 1 | / |

2 | Charger | piece | 1 | / |

3 | USB Cable | piece | 1 | / |

4 | User Manual | piece | 1 | / |

5 | piece | 1 | / | |

6 | Warranty Card | piece | 1 | / |

7 | Packing List | piece | 1 | / |

8 | Software CD | piece | 1 | Limited to Different Models |

9 | Product Suites/Box |